JOB ORIENTED TRAINING INSTITUTE IN KOLLAM FOR BETTER PRODUCTIVITY

Are you looking for the best job-oriented training institute in Kollam to boost your career prospects? Look no further than Ezdan Institute of Technology! With our specialized training programs in Mechanical, Civil, Electrical, and Fire and Safety courses, we ensure that you are job-ready and equipped with the necessary skills to excel in your field.

Mechanical course

Looking for job-oriented mechanical courses in Kollam? Look no further than Ezdan. Our wide range of courses, from Diploma to Advanced Diploma, are designed to provide students with the technical support they need to succeed in the mechanical stream and excel in their careers. Choose Ezdan for the best job-oriented mechanical courses in Kollam.

Civil Course

If you're looking for job-oriented civil courses in Kollam that focus on design and construction, Ezdan has got you covered. Our courses provide hands-on practical training to prepare you for a successful career in the civil sector. So, enroll in our courses today and get on the path towards a fulfilling career in civil engineering.

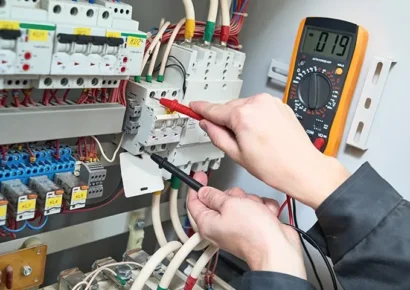

Electrical Course

Looking for job-oriented electrical courses in Kollam that can help you become an expert in the field? Look no further than Ezdan! Our electrical technical courses are designed to provide you with value-based and job-driven training that can help you excel in the industry. With our courses, you'll receive the best training for the leading electrical courses in the field. So, join us at Ezdan and kickstart your career as an electrical expert.

Fire and Safety Course

Are you interested in a profession in fire and safety courses in kollam? You only need to look at Ezdan! Our fire and safety courses are made to give you the greatest instruction possible so you may become an authority in the subject. You can select the Health, Fire, and Safety course that best meets your professional objectives from a vast selection we offer.

EZDAN

-

Best Job Oriented Training Institute in Kollam

At Ezdan, we are committed to providing the best job-oriented training in Kollam. Whether you’re looking to start your career or advance in your current one, Ezdan is the ideal destination for all technical aspirants. So, study, graduate, and start working with Ezdan today! Choose the best job-oriented training institute in Kollam and take the first step towards a successful career.

OUR MOST

POPULAR COURSES

WHY

LEARN WITH

OUR COURSES?

Our courses are job-oriented, which means that we focus on practical training that prepares you for the challenges of the workplace. Our expert trainers and educators bring real-world experience to the classroom, ensuring that you have everything you need to succeed in your career. At Ezdan, we have a well-structured infrastructure for practical training. We have state-of-the-art facilities that are equipped with the latest technology, ensuring that you have access to the tools and resources you need to excel in your field.

Learn

GRADUATE

WORK

WHAT OUR

STUDENTS

HAVE TO SAY

Akash Sethu

Thejus Chandran

Muhammad Roshin N

Sumesh S

Samyukth Santhosh

Mahesh N

Our placement history

100% placement assistance

Sumesh S

Safety Officer |

Yalavarti Projects Pvt Ltd.

Thejus Chandran

Safety Officer | Micron Electricals

Muhammed Roshin N

Site Engineer |

Kalhara Building Concepts

Nasim Naseer

Safety Officer | Micron Electricals

Akash Sethu

Site Engineer |

Kalhara Building Concepts

Samyukth Santhosh

Safety Officer |

Yalavarti Projects Pvt Ltd.